The molding window analysis is used to calculate the best preliminary process settings for your study.. this analysis quickly provides you with recommendations for the injection time, mold temperature, and melt temperature to use as preliminary inputs for a fill+pack analysis.. A molding window analysis helps you to determine what material you should be using, determine the number of gates and understand you part thickness in your design. learn how to set one up here.. Molding window analysis you can use the molding window analysis to calculate the best preliminary process settings for your study. setting up a molding window analysis the following table summarizes the setup tasks required to prepare a molding window analysis. the setup tasks below are for non fiber-filled, or fiber-filled thermoplastic materials..

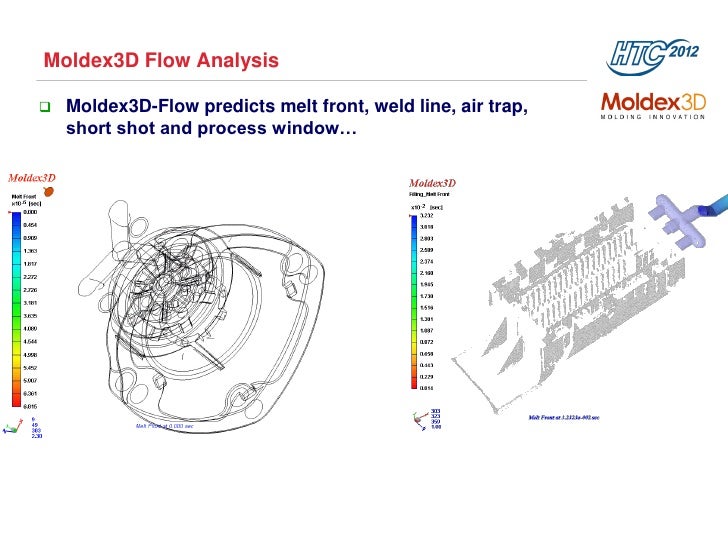

The optimization of injection molding processes using design of experiments problem figure 1 shows the process window for an injection molding process in terms of the injection velocity analysis, and quality control. the results of regression analysis are shown in figure 2. the. The molding window analysis is used to calculate the best preliminary process settings for your study.. this analysis quickly provides you with recommendations for the injection time, mold temperature, and melt temperature to use as preliminary inputs for a fill+pack analysis.. Select molding window and click analyze. molding window analyses output one result. the zone (molding window) result shows how different combinations of melt temperature, mold temperature and injection time impacts on the quality of the finished part. select the zone (molding window) result in the study tasks pane..